What is Die-Cutting?

Die-cutting is a specialised process used to create precise shapes from pressure-sensitive adhesive tapes and other flexible materials. Using advanced machinery and tooling, we transform raw materials into customised components for diverse industries, including automotive, aerospace, electronics, medical and more.

Our extensive capabilities allow us to produce a wide range of custom die-cut shapes, including kiss-cuts, fingerlifts, pull tabs, and complex configurations, all tailored to your exact specifications.

Die-cutting Capabilities

Our die-cutting capabilities include both rotary and flatbed methods, enabling us to provide solutions tailored to your specific requirements:

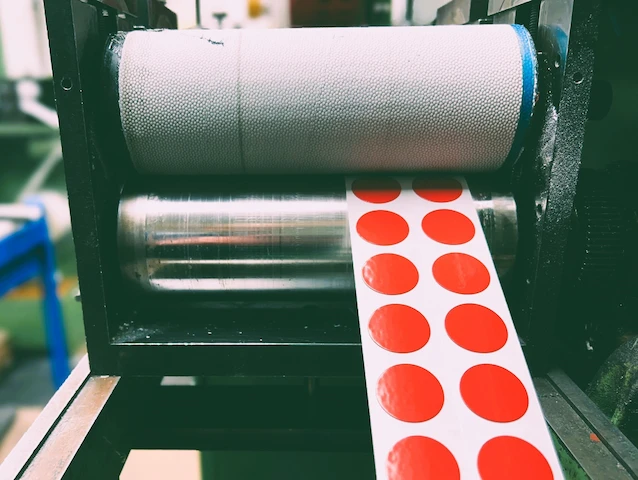

Rotary Die-Cutting: Ideal for high-volume production, rotary die-cutting uses a cylindrical die to create precise, repeatable shapes at high speeds. This process is efficient and accurate, making it suitable for large quantities of identical parts.

Flatbed Die-Cutting: Designed for applications that demand precision and detail, flatbed die-cutting uses a hydraulic press and tooling to cut shapes. Although generally slower than rotary die-cutting, this method is well-suited for lower volume or intricate designs where absolute precision is essential.

Extensive Experience

Since 1980, we have excelled in providing high-quality die-cutting services. Our well-equipped facilities and skilled team ensure each custom part meets stringent quality standards. With a commitment to precision and customer satisfaction, we consistently deliver tailored die-cut solutions that meet the unique needs of our clients.

We always strive to achieve maximum efficiency and yield from both our raw materials and those supplied by customers, helping to reduce waste and lower costs.

Contact us today to learn how our expert die-cutting solutions can meet your adhesive tape needs.

Benefits of die-cutting

Accurate and consistent cutting

Identical and precise shapes and sizes

Reduced material waste and labour costs

Tailored fit to your application

Cost-effective solution

Improved production process of end users

Free Consultation

Our team of experts is ready to help! Submit your details below for a no-obligation consultation on your project. We will respond as quickly as possible.

Prefer to talk?

You can always give us a call instead of filling out the form. Our team of experts are on hand to answer your questions.

Give us a call on

Tangent News and Insights

Explore the latest in Adhesive Tape Innovations and Industry Insights